News Categories

Contact Us

020-86988980

- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

News

Current Location:Home > News > News

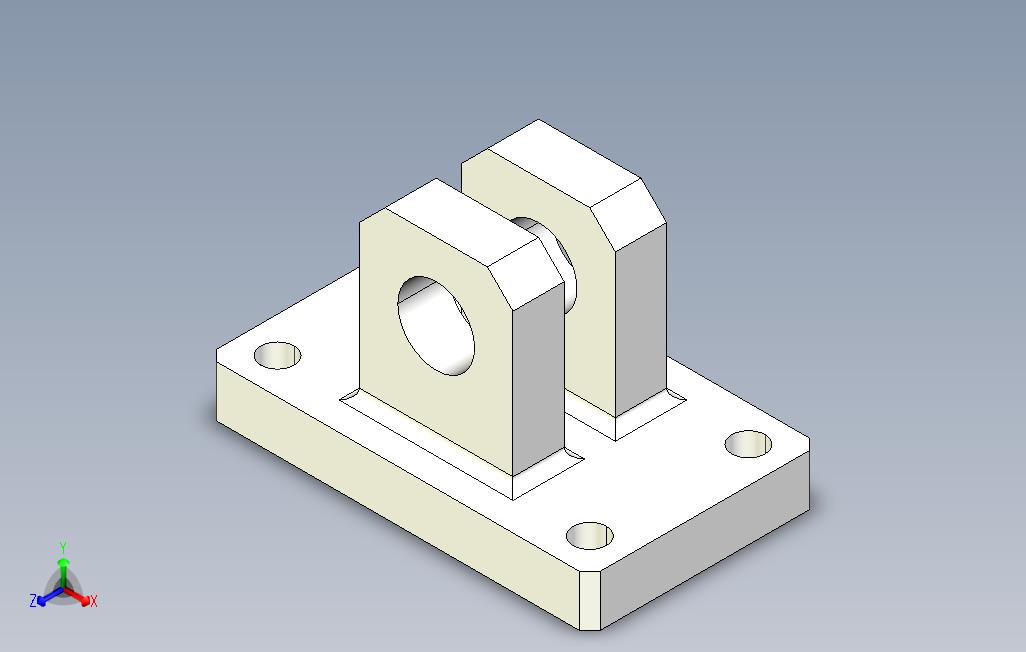

From CAD to CNC The Importance of Accurate 3D Modeling in Manufacturing

Add Time:2025-07-08

The Critical Link Between Design and Production

In modern manufacturing, the journey from concept to finished product relies heavily on two key technologies: Computer-Aided Design (CAD) and Computer Numerical Control (CNC) machining. Accurate 3D modeling serves as the essential bridge between these systems, ensuring design intent is perfectly translated into physical parts.

Why Precision in 3D Modeling Matters

. First-Time Manufacturing Success

Accurate models prevent costly trial-and-error machining, reducing material waste and machine downtime.

. Dimensional Integrity

High-precision models ensure all features-holes, threads, surfaces-are machined to exact specifications without interpretation errors.

. Automated Toolpath Generation

Modern CAM software directly converts 3D geometry into toolpaths, making model accuracy paramount for proper cutter movements.

. Interference Prevention

Properly modeled parts help CAM programmers avoid tool collisions with workholding fixtures or the part itself.

Best Practices for CNC-Ready 3D Models

- Maintain Watertight Geometry - Ensure all surfaces form complete solids without gaps or overlaps

- Specify Tolerances Appropriately - Differentiate between critical and non-critical dimensions

- Include Machining Allowances - Account for material removal in subsequent operations

- Model Realistic Radii - Avoid sharp internal corners that can't be produced with round cutters

- Consider Tool Access - Design features that standard cutting tools can actually reach

The Cost of Inaccuracy

Poor 3D modeling leads to:

- Scrapped parts and wasted materials

- Extended machine setup times

- Rework and manual finishing

- Delayed production schedules

- Potential product failures in the field

By investing in precise 3D modeling upfront, manufacturers achieve smoother CNC workflows, higher quality parts, and ultimately, more profitable operations. In today's competitive landscape, CAD accuracy isn't just helpful- it's a business imperative.

#CNC#Manufacturing#PrecisionEngineering#MachinedParts#IndustrialDesign