News Categories

Contact Us

020-86988980

- Guangzhou Sinoth Import and Export Co., LTD

Tel: 020-8968-8980

Website:www.gzsynoth.com

Email: belinda@dginfa.com(24 hours online)

Phone: +86 189 2740 6786

Address: No 5, Jinshi Three Street, Shiling Town, Huadu District,Guangzhou City, Guangdong Province

News

Current Location:Home > News > News

Applications of CNC in Humanoid Robots

Add Time:2025-09-26

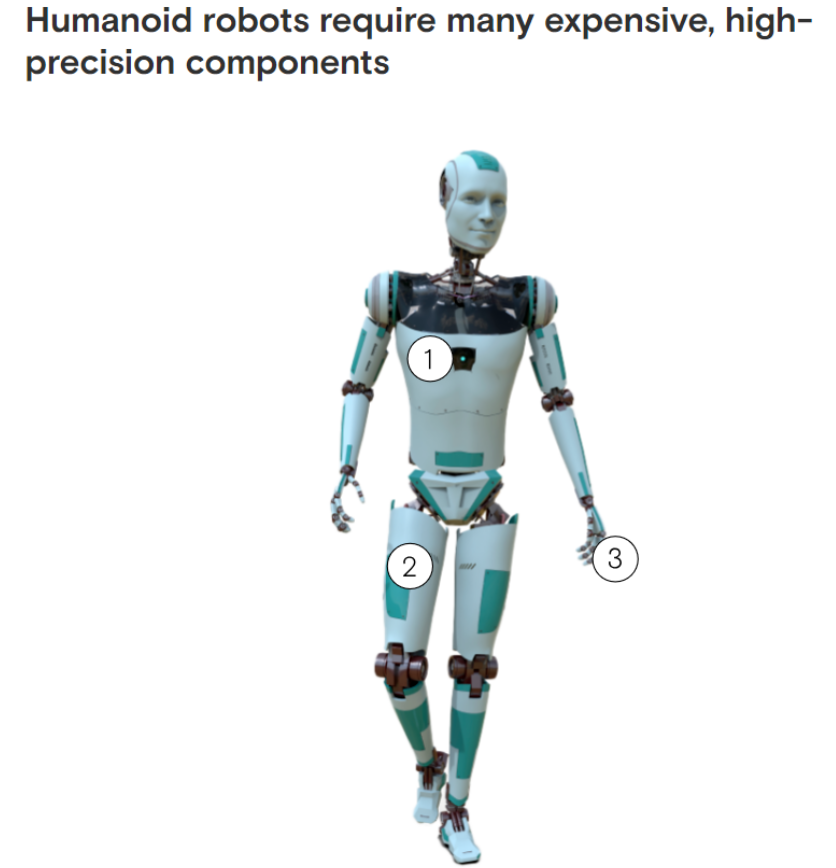

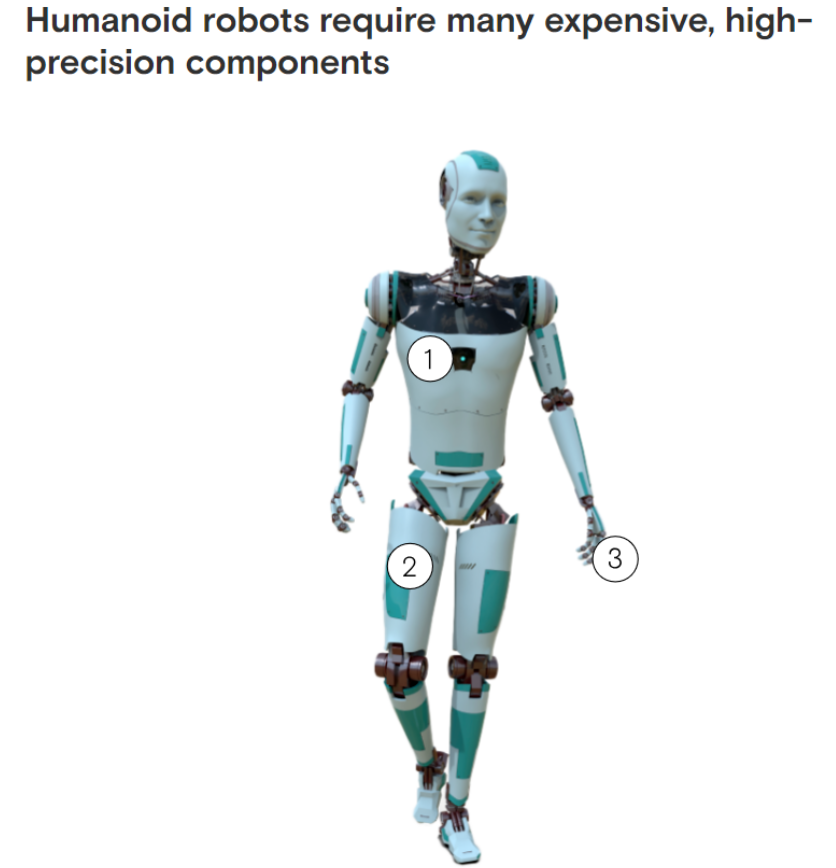

CNC (Computer Numerical Control) technology is primarily applied to high-precision component manufacturing and motion control optimization in humanoid robots, laying the foundation for their flexible movement and structural reliability.

First. High-Precision Manufacturing of Core Components

Humanoid robots require miniaturized, high-tolerance parts to mimic human movement, and CNC machines are irreplaceable in this process:

- Joint components: CNC milling/turning machines produce precision gears, bearings, and reducers (e.g., harmonic reducers) with tolerances as low as +/-0.001mm, ensuring smooth joint rotation without jitter.

- Structural parts: CNC machining of lightweight materials (aluminum alloy, carbon fiber composites) creates robot skeletons and limb frames, balancing strength and weight for natural movement.

- End effector parts: CNC processes grippers or "hands" with fine textures and precise clamping structures, enabling robots to handle small objects (e.g., a pen) stably.

Second. Motion Control and Trajectory Optimization

Second. Motion Control and Trajectory Optimization

CNC's mature numerical control logic is adapted to optimize robot movement accuracy:

- Trajectory planning: Similar to CNC machine tool path programming, it pre-calculates the movement paths of robot limbs (e.g., arm lifting, leg walking) to avoid collisions and ensure linear/smooth motion.

- Multi-axis synchronization: Advanced CNC systems support 6 axis control, coordinating the movement of multiple robot joints (e.g., shoulder, elbow, wrist) to simulate complex human actions like "twisting a bottle cap".

- Dynamic error correction: Real-time feedback (via sensors) and CNC algorithm adjustment compensate for motion errors (e.g., slight deviations due to load changes), maintaining movement precision.

First. High-Precision Manufacturing of Core Components

Humanoid robots require miniaturized, high-tolerance parts to mimic human movement, and CNC machines are irreplaceable in this process:

- Joint components: CNC milling/turning machines produce precision gears, bearings, and reducers (e.g., harmonic reducers) with tolerances as low as +/-0.001mm, ensuring smooth joint rotation without jitter.

- Structural parts: CNC machining of lightweight materials (aluminum alloy, carbon fiber composites) creates robot skeletons and limb frames, balancing strength and weight for natural movement.

- End effector parts: CNC processes grippers or "hands" with fine textures and precise clamping structures, enabling robots to handle small objects (e.g., a pen) stably.

CNC's mature numerical control logic is adapted to optimize robot movement accuracy:

- Trajectory planning: Similar to CNC machine tool path programming, it pre-calculates the movement paths of robot limbs (e.g., arm lifting, leg walking) to avoid collisions and ensure linear/smooth motion.

- Multi-axis synchronization: Advanced CNC systems support 6 axis control, coordinating the movement of multiple robot joints (e.g., shoulder, elbow, wrist) to simulate complex human actions like "twisting a bottle cap".

- Dynamic error correction: Real-time feedback (via sensors) and CNC algorithm adjustment compensate for motion errors (e.g., slight deviations due to load changes), maintaining movement precision.